Choosing the right manufacturing process is pivotal in the creation of any product. Among the various methods available, aluminum extrusion and injection molding stand out as two of the most widely adopted manufacturing processes in the industry. While both processes are designed to shape materials into products, they each have unique attributes and benefits that make them suitable for specific types of projects. In this article, we will delve into the nuances of aluminum extrusion versus injection molding, explore the cost implications of each method, and guide you on how to select the most appropriate process for your manufacturing needs. Whether you're considering precision aluminium extrusion for its versatility or injection molding for its precision, understanding the core differences will aid in making an informed decision.

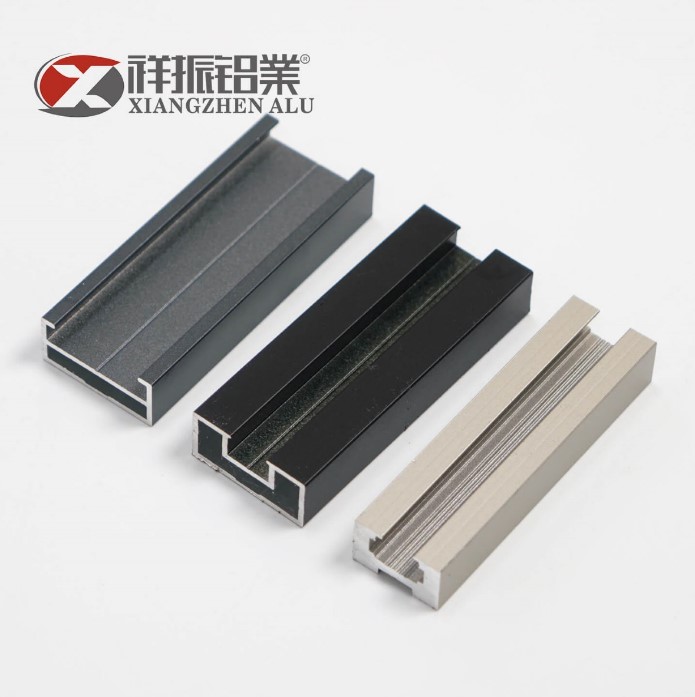

Aluminum extrusion is renowned for its ability to fabricate continuous lengths of aluminum profiles with a wide array of cross-sectional shapes. This process involves pushing heated aluminum billets through a die, tailored to the desired cross-section. The extruded aluminum profiles can then be cut to length and utilized in various applications, from intricate extruded aluminum moldings in construction to components in automotive manufacturing.

Cost-Effectiveness: When comparing extrusion molding vs injection molding, extrusion emerges as the more cost-efficient option for certain production scales. The tooling required for extrusion is generally less expensive, leading to lower setup costs, particularly beneficial for limited production runs.

High Strength-to-Weight Ratio: Aluminum's inherent high strength-to-weight ratio is amplified through the extrusion process, yielding products that are both lightweight and durable. This characteristic is especially valuable in industries where weight reduction is paramount without compromising structural integrity.

Versatility in Design: The precision aluminum extrusion process allows for the creation of complex cross-sectional profiles that are challenging to achieve with injection molding. This adaptability makes it a preferred method for a broad spectrum of custom applications.

Eco-Friendly: Aluminum's recyclability combined with the energy efficiency of the extrusion process underscores the environmental benefits of this method. Aluminum extrusion distributors often highlight this aspect to appeal to eco-conscious consumers.

In contrast to extrusion, injection molding involves the injection of molten materials into a mold cavity to form the desired shape. This process is highly regarded for its precision and suitability for mass production. Materials typically used include various plastics, each offering different properties to meet the demands of the final product.

Aluminum Extrusion For Formwork

High Precision: Injection molding's capability to produce components with intricate details and tight tolerances is unmatched. This precision is essential for complex parts where dimensional accuracy is critical.

Efficiency in Large Production Runs: For high-volume production, injection molding is often the go-to process due to the lower per-unit cost achieved as production quantities increase.

Material Diversity: The process can handle a multitude of materials, including diverse plastics and elastomers, enabling manufacturers to tailor the properties of the final product such as impact resistance, flexibility, or thermal stability.

Color Flexibility: Unlike extruded aluminum moldings, injection molded products can be created in a vast spectrum of colors directly within the process, facilitating branding and aesthetic customization without the need for post-processing.

Both aluminum extrusion and injection molding have their advantages, and the right choice depends on your specific needs. It's important to carefully consider your product's requirements, design, and materials to determine which process is the best fit. By making the right choice, you can ensure that your product is manufactured efficiently, cost-effectively, and to the highest quality standards.

Anyway, if you are looking for an aluminum extrusion supplier, XIANGZHEN is your great choice! We offer a wide range of aluminum extrusions. Don't hesitate to contact us and shop now at the best price!